Environmental protection covers both the reduction of industrial activity impact, water-saving solutions and energy efficiency in products..

INDUSTRIAL MANAGEMENT

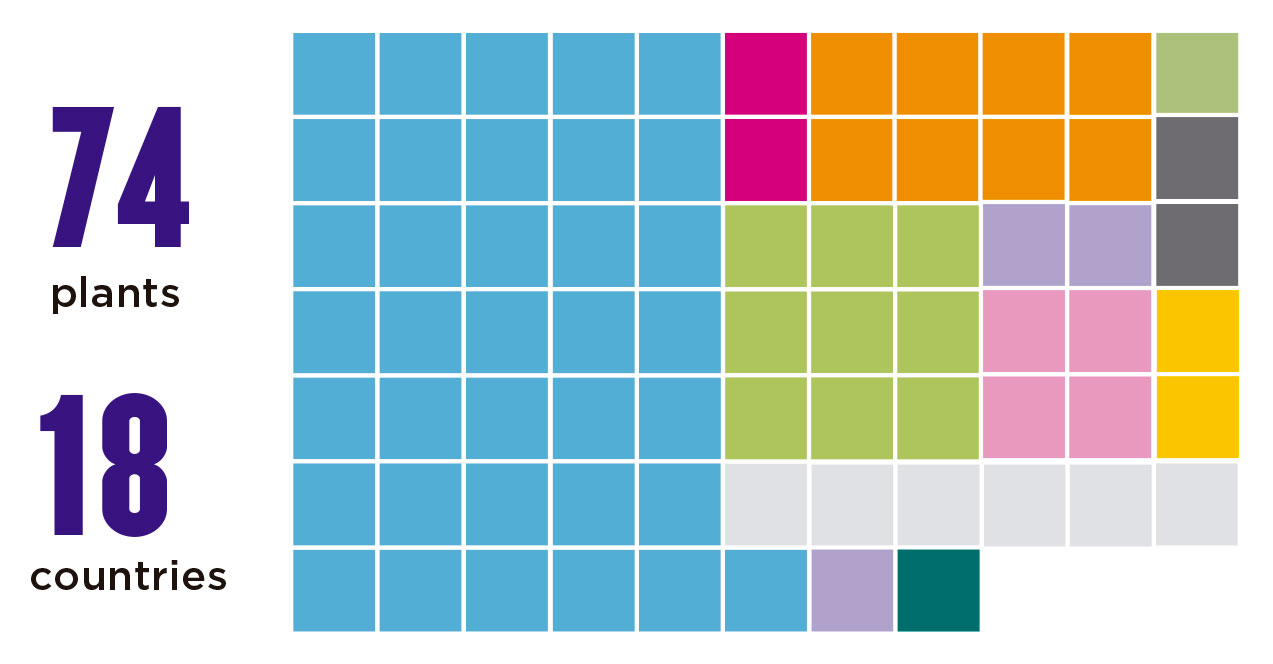

Year marked by the recovery of demand in domestic markets and the Group brands positioning as integral suppliers of products for the bathroom space. Progress has been made in 2014 in consolidating a flexible industrial capacity that adapts easily to meet both the specific needs of local markets and the various large-scale projects worldwide.

To this end, an optimization plan was rolled out to the 74 plants which focused on streamlining overal costs through continuous productivity improvement, paying special attention to centers with the greatest margin for improvement.

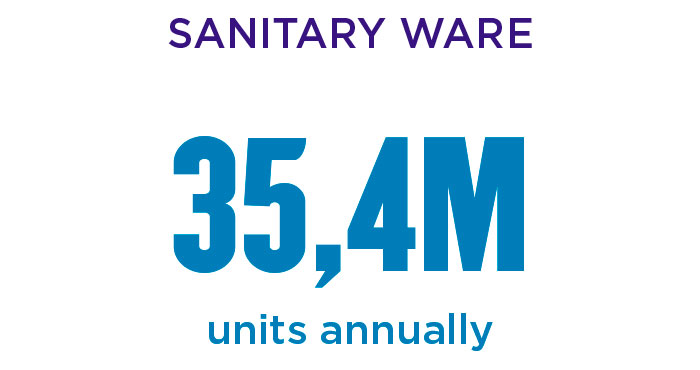

SANITARY WARE PLANTS

New facilities have been commissioned and the capacity in existing centers has been expanded, thanks to the reconfiguration plan for sanitary ware plants deployed in previous years, the recovery of demand in European markets and sustained growth forecasts in emerging markets.

In the region of Western Europe and Africa production has started in a second plant in Anadia (Portugal), aimed at serving both the domestic market and the demand generated by new contracts signed. The first plant in Anadia and the Leiria plant, also in Portugal, were expanded with the installation of two pressure machines for toilets and sinks. The factories in Morocco and Egypt posted excellent productivity rates and practically reached 100% capacity, rolling out 2.3 and 2.1 million pieces per year, respectively. For the first time in several years, the plants of this region have worked continuously all year round.

The main actions in Central and Eastern Europe focused on the modernization of facilities by incorporating various pressure casting machines for toilets in Switzerland, Austria and Poland. In Poland, the expansion works at the Gliwice plant were also approved, a project carried out over 2015 and the first half of 2016. Various efficiency and production process improvements have continued to be applied in Russia.

The extension carried out between 2013 and 2014 has doubled its production capacity and upgraded its facilities, automating many of its processes.

The largest industrial investments in Asia-Pacific were the expansion of the Dewas (India) and Tangshan (China) plants.

Two other high value-added actions stand out in the Asia region, underscoring the Group’s flexibility to local needs. On the one hand, the Suzhou plant built an assembly line of smart toilets — featuring new technology and innovations such as In-Wash and In-Tank — which have been very successful in the country. On the other hand, the acquisition of the Indian company Espiem allows incorporating two polypropylene tank and plastic seat factories located in Chennai and Pantnagar. These are the Group’s first plants in this business line, which allow concentrating production of these products in India for the entry-level market segment for all Asia.

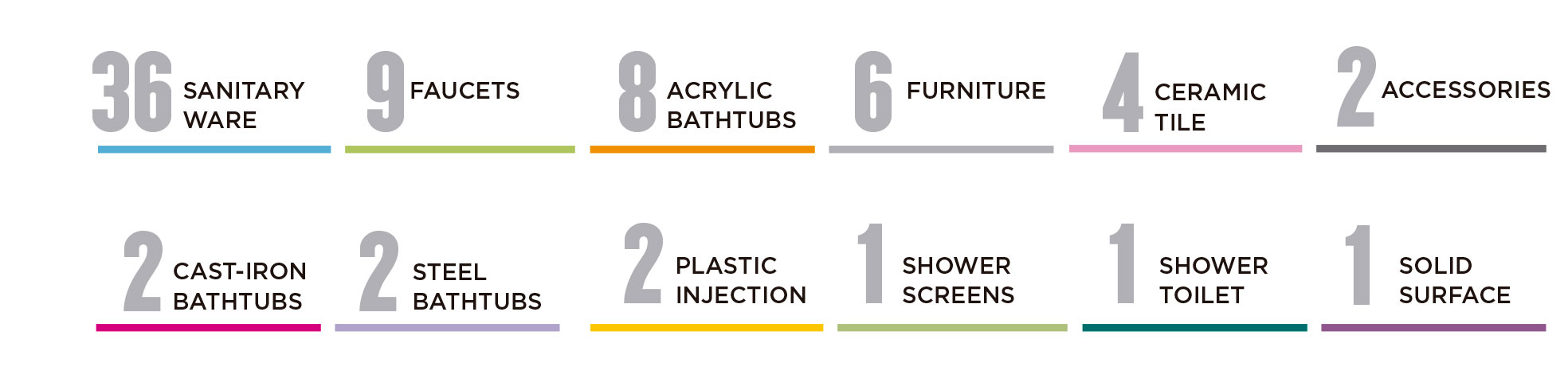

INDUSTRIAL PLATFORMS

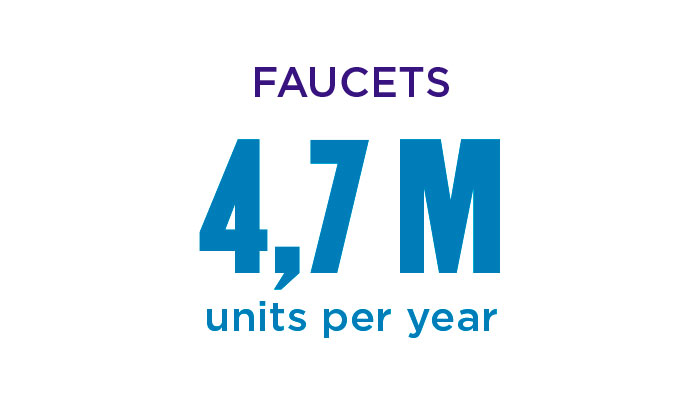

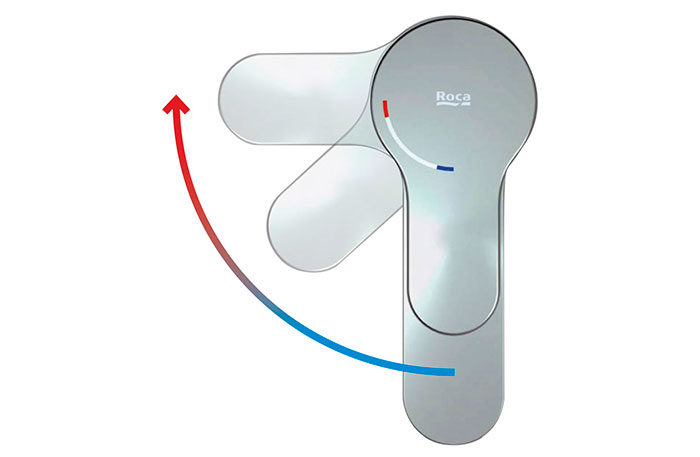

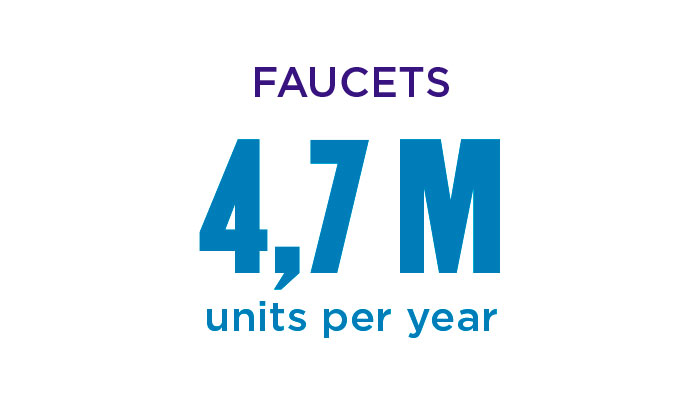

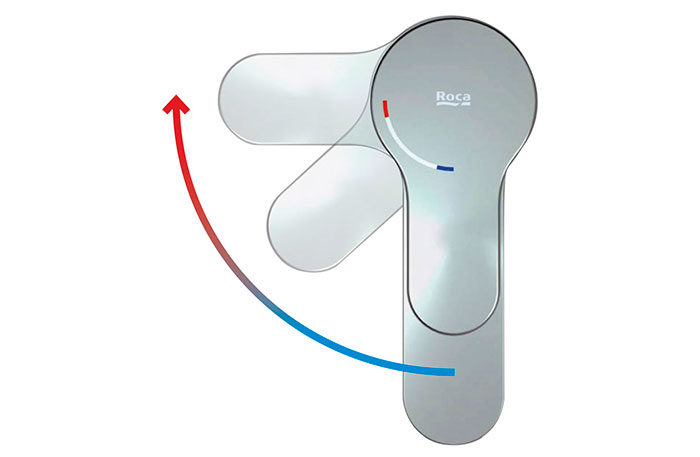

The consolidation of the platform concept allows new launches in the development of thermostatic, electronic and mixer faucets, as well as the expansion into showers and shower heads. The Box project — the universal basis for all recessed faucets in the Group — is also set to launch in 2015. In terms of product, worth noting is the launch of new sets of faucets for local brands, which record a sales growth of 50%, and a total sales increase in faucets of 7%.

FY 2014 has been decisive in expanding the Faucets business, both geographically and in the development of value-added innovations to position the Group as a world leader in the category. With the aim of consolidating in key markets, actions have been carried out in all operating regions. In terms of project scale, the commissioning of the plant in Recife (Brazil) stands out. It is the first complete cycle plant in Brazil, boasting annual production of 500,000 for Roca and Celite brands. In the Asian region, the plant in Suzhou (China) has taken over the production of Tangshan and has added new automatic sanding robots, while the plant in Bhiwadi (India) has begun production of zamak handles, a technology developed by the Group exclusively in this center. In Eastern Europe the Znojmo (Czech Republic) assembly unit was consolidated as a logistical base for the region, and the Cheboksary (Russia) plant has also started operations. In Western Europe, technology and productivity improvements have been launched in Cantanhede (Portugal) and Gavà (Spain).

Faucet Platform. New complete cycle plant in Brazil and upgrades in other plants.

The consolidation of the platform concept allows new launches in the development of thermostatic, electronic and mixer faucets, as well as the expansion into showers and shower heads. The Box project — the universal basis for all recessed faucets in the Group — is also set to launch in 2015. In terms of product, worth noting is the launch of new sets of faucets for local brands, which record a sales growth of 50%, and a total sales increase in faucets of 7%.

The Furniture business also saw significant growth in sales in 2014, close to 15%, thanks mainly to the excellent performance by the Roca, Laufen and Jika brands. In industrial terms, the new assembly plant in Jundiai (Brazil) started operations, with an initial annual capacity of 35,000 pieces for the Roca and Incepa brands. The Anadia (Portugal) and Znojmo (Czech Republic) centers were also consolidated. This business currently has two full floors and four assembly units, and its main markets are Russia, Spain and China, with significant growth prospects in Brazil. The new product launches include the launch of the Roca brand Prisma and Heima collections, and the extension of the PRO series and Laufen’s Kartell collection.

Started in 2013, the Screen business has renewed its catalog with the launch of Roca’s Fusion-N and Ura series. With plants in Nanhai (China) and Caldes de Montbui (Spain), its main markets are Spain, Norway and Portugal. Australia and China are in its sights for expansion in the short-term.

THE INDUSTRIAL PLATFORM MODEL HELPS STREAMLINE DEVELOPMENT COSTS AND MEET SPECIFIC DEMAND IN LOCAL MARKETS

The Acrylics business has intensified Solid Surface and gel-coat production with initiatives in various plants. In Portugal we have launched a continuous casting machine for shower trays to ensure supply of the Terran model, and we have developed the Helios model. In Poland we worked on rolling out Solid Surface for custom projects and implemented enhancements to the gel-coat line. In Gavá we industrialized a new anti-slip product in the acrylic shower tray line.

Finally, the Roca Installation Systems (RIS) business has developed an innovative electronic drive panel for recessed tanks featuring dual flush and presence sensor. We also designed a new split-rack recessed tank which is easier to package, aimed at the DIY channel. We updated the design of the Duplo WC tank with new flushing options and the possibility of installing shower toilets. Likewise, we developed a new universal rack for public urinals.

CERAMIC TILE PLANTS

The Group’s Roca Tiles division has completed its production and logistics concentration operation at the Vall d’Uxó facilities (Castellón, Spain), following the cessation of activity at the plant near Barcelona. The Vall d’Uxó center now operates at 100% capacity while it has also made significant progress in stock reorganization to align production to the real needs of its main markets: Spain and rest of Europe. The main investments have focused on increasing the number of digital injection decorators, a technology that has transformed the ceramic tile market as it allows greater product customization, regardless of format.

Thanks to their increased capacity in previous years, the plants in Brazil have maintained their production level to meet the demand of the local brand Incepa, fueled in recent years by its repositioning in the premium segment. At the end of 2014 a supercompactor was installed in Campo Largo, aimed at producing large-format units. It became operational in the first quarter of 2015.

Digital injection decorators allow greater product customization.

QUALITY AND ENVIROMENT

In parallel with its industrial productivity optimization strategy, the Group is working to develop a network of quality management departments, coordinated from headquarters in Gavà (Spain), to address the needs of the local markets. Following the strategic plan established in 2013 and in order to implement a quality managment system based on ISO 9001, in 2014 we focused on including new production centers as part of this certification and aligning with the new version of the standard, which takes effect in 2017.

The W+W suspended toilet and sink, example of water-saving innovation.

Another key element of our business is ensuring the same quality level for all product lines, regardless of the plant where they are made. In this sense, the centers have improved their ability to respond to new release validations. Proof of this has been the joint development of a bathroom series by technicians from the Gala and Sanitana brands in collaboration with Gavà. Quality managers work jointly via a common technology platform that streamlines the exchange of knowledge and reduces the validation time for new developments. The quality department has also faced the reorganization of its work system, adopting a management-by-process improving work planning and results.

To reduce the impact of industrial activity on the environment a global reporting network was established and a Group-wide environmental management system started to be implemented, aiming to apply common, high-level criteria. Worth noting in this regard is the work done in the new faucet plant in Recife (Brazil), which has received all local certifications in record time. The Group’s global indicators include reducing gas consumption by 6% and reducing CO2 emissions by 5.9%.

Environmental protection covers both the reduction of industrial activity impact, water-saving solutions and energy efficiency in products..