The various Roca centenary celebrations held in 2017 revealed that one of the main skills allowing the Group to reach this anniversary has been keeping an eye on the ups and downs of the economy and technology in order to adapt its industrial and commercial capacity to market demand. In keeping with this objective, and given the scale of the company in the past two decades, an organizational model has been implemented in recent years, based on three main aspects:

This management model, already fully consolidated around action areas, makes it possible to consider the Group as the leading global operator in the industry and provides it with a sound structure to meet market challenges in the digital era.

PRODUCTION PLANTS

78

EMPLOYEES

23,615

COMMERCIAL PRESENCE

170

countries

In 2017, the cross-functional value chain management model moved forward through the creation of a corporate Supply Chain unit and the expansion of industrial platforms to new products. In their respective responsibilities, all integrated corporate management units must address and respond to current market trends, such as growth in nontraditional categories, shorter product life cycles, the need for shorter production series and customer expectations for faster delivery times.

Beyond the traditional task of designing and updating collections, the Design and Innovation corporate unit performs a company-wide function at two levels: geographically and in the development of our offering. On the one hand, the unit coordinates a network of six centers—Gavà (head office), Laufen (Switzerland), Nanhai (China), Jundiaí (Brazil), Taichung (Taiwan) and Ranipet (India)—that cater to local product adaptations with greater proximity to markets while exploring synergies for designing new collections. Likewise, the unit works to roll out innovation and extend excellence to all bathroom space elements, in collaboration with the respective industrial platforms, and placing Group brands as benchmarks in all categories.

This work methodology addresses current market demand: more technologically advanced solutions but with shorter time-to-market development time), achieved thanks to comprehensive planning of each new launch (from idea to distribution) and leveraging the latest technology at the prototype stage—rapid prototyping—via machining centers and 3D printers and testing.

Key new products for the year were presented at the international ISH trade fair in Frankfurt, most notably Roca's Carmen collection which pays homage to one of the most emblematic models of our brand, updated with the rimless solution. Other new applications include the high-quality Fineceramic ceramic material in the Roca Beyond and the Laufen Val collections.

Other new proposals developed in collaboration with designers such as Giorgio Armani were presented, such as the Armani/Roca Baia, Ludovica and Roberto Palomba collections, with a new expansion of Kartell by Laufen. New models of Roca's In-Wash® and Laufen's Riva toilets were also displayed, protagonists of the brand catalogues throughout the year.

In other product categories, we should also mention the launch of the new ThinBig ceramic tile, a new thin (6 mm), lightweight, versatile and durable ceramic tile which can adapt to any surface.

In keeping with its two-fold aim to participate in the advance of the bathroom space and support new designers, Roca organizes the Jumpthegap contests, which promote the design of innovative concepts for the bathroom space, and the One Day Design Challenge, an express bath item contest. In 2017 both events had the greatest international impact in their history. The seventh Jumpthegap contest broke records with more than 6,000 entries from 134 countries. The One Day Design Challenge held its first edition in Moscow, London, Lisbon, Oman and Shanghai.

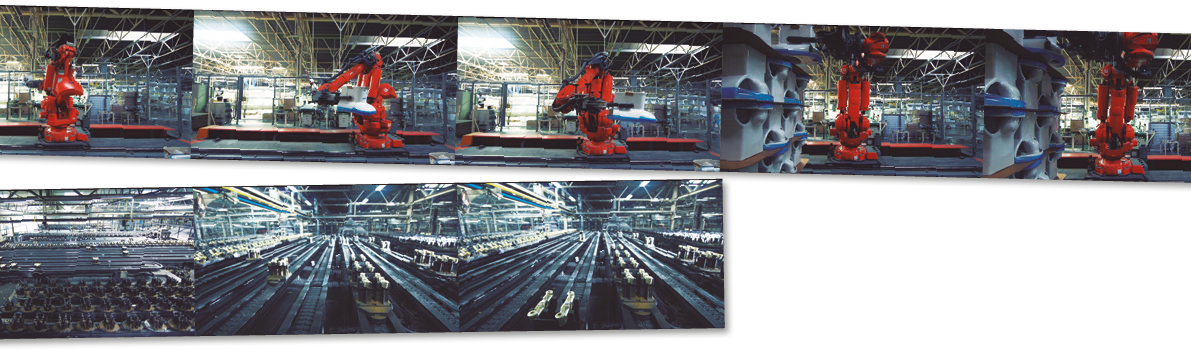

Following the acquisitions in Turkey and Mexico the year before, in 2017 the Group managed an industrial network comprising 78 own factories in 18 countries, with capacity to manufacture and distribute all the categories comprising the bathroom space. The organization's global management system is applied to the industrial process through a proximity-based production model which allows plants to respond with utmost flexibility to unique market demands, both in terms of production volume and the need for product customization to local preferences.

This proximity-based production model is managed with two systems. In the case of sanitaryware—which pose transport difficulties due to volume—, we use a large-series production system in plants strategically located to meet the demand of major markets and their surroundings. In production for other bathroom space categories, an industrial platform system is used to standardize basic technical components of each product, pending further customization of the final product depending on the specific demand in each market. In both systems, the crossfunctional management model promotes identification and sharing of best practices in both product development and efficiency indicators.

SANITARYWARE

39

FAUCETS

10

ACRYLICS

9

FURNITURE

6

BATHTUBS

4

FIXTURES

2

INJECTION MOLDING

2

SMART TOILETS

1

SHOWER SCREENS

1

TILES

4

PRODUCTION PLANTS IN

18

countries

Corporate unit managing a total of 39 plants, which position the Group as a world leader in sanitaryware production. Our main investments in 2017 were aimed at expanding the production capacity of our centers in Poland, Croatia and Russia, as well as constructing a new plant in Indonesia.

35.4

million units per year

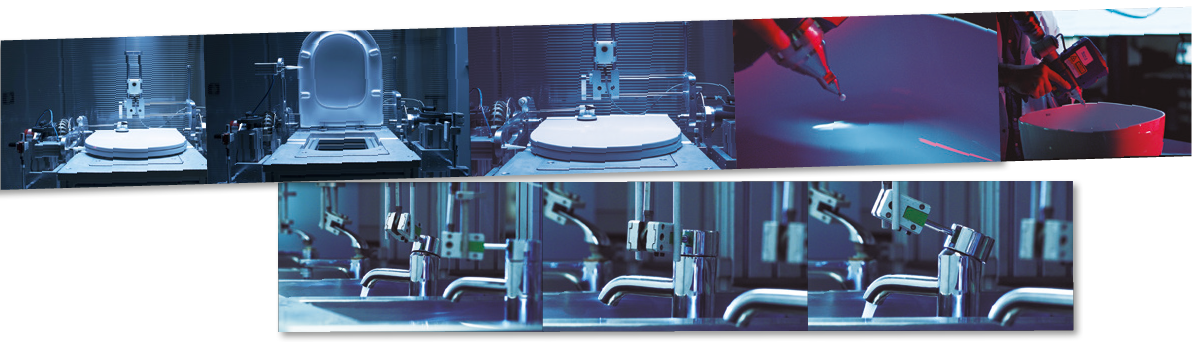

Platform currently managing eight full-cycle plants and four assembly centers, in one of the fastest-growing categories in terms of sales and technological development in recent years.

5.6

million units per year

Platform comprising two full-cycle factories and four assembly centers, which have evolved in recent years as flexible solutions. These centers were developed for integration with other product lines (sanitaryware, mirrors, lighting fixtures, etc.).

684,000

units per year

This year we focused on restructuring the product offer to consolidate a range to establish the Group as a leader in the category.

107,000

units per year

Synthetic materials stand out as one of the main lines of development for new products as they allow new possibilities for custom design and production.

The launch of new formats, produced in both Spanish and Brazilian factories, has helped reposition the ceramic tile supply in the upscale segment.

Platform with great potential for development, which has reached the milestone in 2017 of launching the first family of proprietary recessed tanks.

The Group's global production model provides the firm with common control protocols to ensure the same quality standards for all products and manufacturing processes in any plant. This requirement is even greater because the supply has become highly diversified with new categories for the bathroom space and because we work with increasingly more suppliers, use more technological features in products and market the products through multiple distribution channels.

The Quality Management unit, also responsible for corporate environmental policy, addresses these stringent requirements through three lines of work, consolidated in 2017.

First, we aim to enhance knowledge sharing with production units through the dissemination of the Group's quality policy, and align teams under the same goals. Second, we conduct internal audits on the various processes and provide technical support to all branches. And third, we ensure customer and user satisfaction by implementing common standards for customer support and by carrying out quality surveys.

The Group's Technical Service also works along these lines. This unit was established at the corporate level to roll out the model already implemented in Spain to major markets where we have a commercial presence.

The model combines phone support—in Spain it handles about 29,000 calls a year—with every corner of the country reached through a network of technical representatives and dealers. Along with Spain, this methodology is used extensively in the markets of Brazil, Bulgaria, China, India, Portugal, Russia, and the United Kingdom. The first phase of implementation in Turkey took place in 2017.

The Group has common control protocols to ensure the same quality standards for products and manufacturing processes in any plant.

The celebration of the Roca centenary in 2017 has been an excellent opportunity to analyze the evolution of the bathroom space business, and very specifically, the evolution of sales and brand management to various audiences, an aspect that in recent years has undergone unique changes mainly due to the impact of the digital revolution in all processes. This transformation context is further complicated by the Group's global presence, as it operates in extremely different countries.

Amidst this environment, the market know-how provided by local business units is key to winning the confidence of influencers and users and ensure that the various Group brands are positioned as eminent brands in their respective segments. Examples of the diversity of actions undertaken in 2017 include the marketing program for the In-Wash smart toilet in Spain. To bolster this flagship product, the company launched a popular advertising campaign plus meetings with distributors and influencers, generating new business opportunities.

Several initiatives have been undertaken to target influencers and clients, including the Think Turf program in India, a knowledge base for architects which has reached more than 1,000 professionals, the opening of the Beijing Roca Gallery (sixth Roca Gallery for the Group, also aspiring to become a meeting place for architecture and design professionals) and opportunities arising from the various centenary celebration events around the world. These celebration events include those held in Lisbon, Prague, Buenos Aires, New York and the network of stores in Australia.

ROCA GALLERIES IN 2017

6

galleries

271

events

59,710

visits

The Group's proprietary distribution model, which reaches every corner of the geographical territory through the presence of the largest possible number of outlets and showrooms, is still used in most markets. To this end, the company is working to reach agreements with local distributors and, in some countries, with some of the most important chains in the industry.

In 2017, this expansion model has begun to be implemented in many African countries. New outlets in high-potential countries such as South Africa, Nigeria, Scandinavia (the first Laufen showrooms in Sweden), Indonesia (where we signed a joint venture with local distributors), and China, boasting 85 new outlets.

The ISH fair in Frankfurt—the most important fair in the industry worldwide—has led to the introduction of a new booth concept which the Roca brand will use in other fairs throughout the year. The concept, dubbed the "Roca Mall", recreates a shopping center featuring different environments. Different spaces representing the various brand collections are set up as the various sections of a mall. After its premiere at the ISH fair in 2017, it has already been replicated in the KBC at Shanghai, Archidex in Kuala Lumpur and Cersaie in Bologna, among others.

Laufen was also featured prominently at ISH, hosting a booth focused primarily on exhibiting key new brand products in an artistic layout, the possibilities of the SaphirKeramik ceramic material and collaborations with new designers. Participation in more local fairs has contributed significantly to boosting the presence of the Group's brands in countries such as Denmark, France, Sweden, the United Kingdom and the United States.

The Group's unique expansion through a distributed sales network was developed in 2017 in high-potential markets such as Indonesia, Nigeria, Scandinavia and South Africa.